After expecting and waiting,the 22nd China International Agrochemical & Crop Protection Exhibition (CAC 2021),which has been postponed for more than one year,will be held as scheduled in this rainy June.It is not easy,therefore as a member of agrochemical industries,we can not be absent.On 22nd to 24th June,Rucca Group will wait you at Booth H00, Hall E7, Shanghai New International Expo Center.

Quickly view the new process technology of suspension concentration!

I.Features of the new high-efficiency inline dispersing wetting and mixing inline dispersing system:

New high-efficiency inline dispersing system,to avoid dust pollution/treatment, totally comply with current environmental protection regulations, reduce labor intensity, greatly improve dispersion efficiency, reduce space requirement and the number of equipment,especially reduce energy and consumption of bead mills.For example,to produce 2m3 pesticide formulations,the equipment only need about 2/3 power compare with existing. Some pesticide formulations may not need to be ground by bead mill. Some formulations can reduce the amount of additives,like surfactants,dispersants and etc. Wetting and dispersing, depolymerization, dust-free, low energy consumption and emptying of powder bucket are completely realized in one machine.

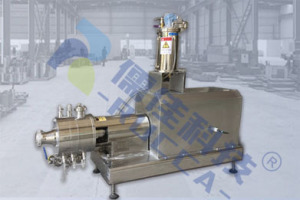

II.EQ inline shearing pump

High mixing efficiency,low energy consumption, to replace shearing machine and mixer with one machine.

III.Hot sale 2020 suspension concentration production machine--Rucca DF60 bead mill

Efficient, stable, increase capacity,reduce costs.

IV.Turnkey project of SC(suspension concentration)

To custom SC production line,could achieve automatic metering, dust-free feeding, fine dispersing, high-efficiency grinding, fast defoaming,easier cleaning and product changing.